Inquiry

TOP

pr center

pr center

Product Development

Seoam produces the world's best products through ceaseless research and development.

Development Performance

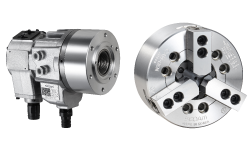

Chuck & Cylinder

Field

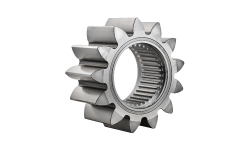

Gear&Curvic coupling

Field

Chuck & Cylinder Field

1999

Developed Seoam’s own big-bore

power chuck and hydraulic cylinder

With the successful manufacturing experience of the first hydraulic chucks in Korea on its own technology and the accumulation of know-how, Seoam has designed and manufactured the ACE series, boldly overcoming dependency on advanced foreign technologies and brought attention to that technology.

Developed super high-speed big-bore power chuck

We devote ourselves to developing new technologies that are one level ahead to actively respond to the new 6-inch NC lathes for super high-speed at 10,000 rpm.

Developed great-bore power chuck

We offer broader choices, having developed large-scaled bore power chucks in 15, 18, 21, and 24 inches in our own technology.

2000

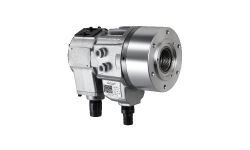

Developed SEOAM’s own closed center

big-bore power chucks and hydraulic cylinders

With the successful manufacturing experience of the first hydraulic chucks in Korea on its own technology and the accumulation of know-how, Seoam has designed and manufactured the ACE series, boldly overcoming dependency on advanced foreign technologies and brought attention to that technology.

Developed great-bore power chucks

We improved the issue of inconvenient chuck replacement with larger through-holes (6' - ¢53, 8' - ¢66, 10' - ¢82) in the same sized chucks. Especially, it works well when processing bar materials..

2005

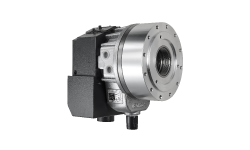

Big-bore power chucks & Cylinders

- short taper type (CAHA-05,YAH-05)

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard hydraulic chucks and cylinders (model expansion) – rotating speed up to 7,000 rpm

ㆍResponded to the demand for twin-spindle machine tools and had the effect of targeting the market of competitive models

Large-scaled closed center hydraulic cylinder

-check valve type (YASC-200)

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard hydraulic cylinders

- Compatible with competitive models

- rotating speed up to 5,500 rpm

ㆍImproved check valves

- Excellent performance and quality to ensure safety and maintain pull force during power outages

2006

Big-bore long hydraulic cylinder

YAHL-10, YAH-15, YAHL-15 CA

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard long hydraulic cylinders (model expansion)

- Expanded standard products in long stroke type

ㆍResponded to the demand for strategic long stroke machine tools and targeted the market of competitive models

Super high speed great-bore hydraulic cylinder

YSGH-08 CA

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own slim hydraulic cylinders (model expansion)

ㆍReduced the burden of equipment with competitive price and targeted the market of competitive models

2007

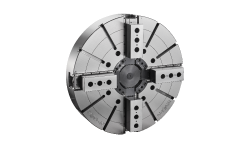

Closed center power chucks CAS, CASL

- 32" and 40"

4-JAW Closed center power chucks

CASF-32", CAS - 40"HC CAH-24"

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own closed center hydraulic chucks (model expansion)

ㆍResponded to the demand for large-scale machine tools and targeted the market of large-scale models

Super high-speed big bore hydraulic cylinder

YSH-05”CA, YSH-10”CA

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own slim hydraulic cylinders (model expansion)

ㆍReduced the burden of equipment with competitive price and targeted the market of competitive models

2008

Closed center power chucks (fine adjustment)

CAS-50", CAS-50"YS, CAS-50" 2ND JAW

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own closed center hydraulic chucks (model expansion)

ㆍResponded to the demand for large-scale machine tools and targeted the market of large-scale models

Closed center power chuck (with detachable adapter)

CAS-15"K, 18"K, CAS-21"K

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own closed center hydraulic chucks -detachable adapter (model expansion)

ㆍResponded to the demand for mid/large-scaled machine tools and targeted the market of mid/ large-scaled models

Super high-speed big-bore slim hydraulic cylinder

YHS-05", YSH-05", YSGH-06"

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own slim hydraulic cylinders (model expansion)

ㆍReduced the burden of equipment with competitive price and targeted the market of competitive models

2009

Super high-speed closed center slim hydraulic cylinder

(YAST-200S, YAST-250S)

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard slim hydraulic cylinders (model expansion)

- Expanded standard products in long stroke type

ㆍResponded to the demand for strategic long stroke machine tools and targeted the market of competitive models

Closed center power chuck (with detachable adapter)

(CAS-24K, CASS-25)

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard hydraulic chucks and cylinders (model expansion)

ㆍ Responded to the demand for mid/large-scaled machine tools and targeted the market of mid/large-scaled models

2010

Big-bore long hydraulic cylinder

(YSH-06, YSGHL-08, YSH-15, YSHL-15)

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard hydraulic chucks and cylinders (model expansion)

ㆍReduced the burden of equipment with competitive price and targeted the market of competitive models

Closed center hydraulic chuck (fine adjustment)

(CAS-32HC, CASF-40HC)

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard hydraulic chucks and cylinders (model expansion)

ㆍResponded to the demand for large-scale machine tools and targeted the market of large-scale models. Had supplied for VT-1150 development,

Closed center hydraulic cylinder (YAST-200S)

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard hydraulic chucks and cylinders (model expansion)

- Expanded standard products in long stroke type

ㆍResponded to the demand for strategic long stroke machine tools and had the effect of targeting the market of competitive models on progress for SKT-5V development

2011

Closed center chuck

H01MA-15, 15A8, 15A11, 18, 18A11, 21,

21A11, 24, 24A11, 28, 32, 36, 40(13types)

ㆍDeveloped larger-scaled closed center hydraulic chucks for HOWA OEM

ㆍResponded to the demand for closed center machine tools and targeted the market of large-scale models

Big-bore long hydraulic cylinder YSHL-21"

ㆍOvercame dependency on advanced foreign technologies of design and manufacturing, having developed its own standard long hydraulic chucks and cylinders (model expansion)

ㆍReduced the burden of equipment with competitive price and targeted the market of competitive models

Gear&Curvic coupling Field

1997~2001

1997~2001

Developed substitute materials for ADI of

large and small forged steel gears

Participated in a government leading industrial technology-based development project jointly with the Korea Institute of Industrial Technology, developed unique gear materials that can be cast and have excellent vibration attenuation capabilities. It contributes to reducing noise and manufacturing costs for large industrial gears.

1999~2001 Developed high-speed gear manufacturing technology

We devote ourselves to developing new technologies that are one level ahead to actively respond to the new 6-inch NC lathes for super high-speed at 10,000 rpm.

2000 Developed small-number-tooth curvic couplings

As a leader in the curvic couplings' localization, developed small-number-tooth curvic couplings for optimal equalization that matches the performance conditions, the key part of the angle division device. It enhances the price competitiveness of applied products.

2002~2005

2002~2005

Development of reducer and gear for

towing locomotive in the Panama Canal

Established gear design and processing technology to achieve localization of gears, and developed gears for towing locomotives in the Panama Canal

2003 Developed gears for centrifugal compressor

Developed high-speed gears that require ultra-high-speed, low noise, and low vibration and established high-precision high-speed gear manufacturing technology to approach customers with a premium image

2006~2007

2006~2007 Developed marine engine gears

Succeeded in localization of gears for marine engines through research and development, and its quality has been verified by the ship classification society and reliability proven both domestically and overseas.

2006~2007 Developed 360T Curvic Couplings

Participated as a leading agency in the government leading project to develop new products of the Small and Medium Business Administration subject to purchase conditions, and developed ultra-precision 360T curvic couplings to achieve domestic/mass production of all types of curvic coupling. It enhances price competitiveness for machine tool manufacturers.

2007 Developed marine engine gears

Developed gears for wind turbines to actively respond to the increasing demand for renewable energy from wind power. We do our best to be the best in the global markets based on technology.